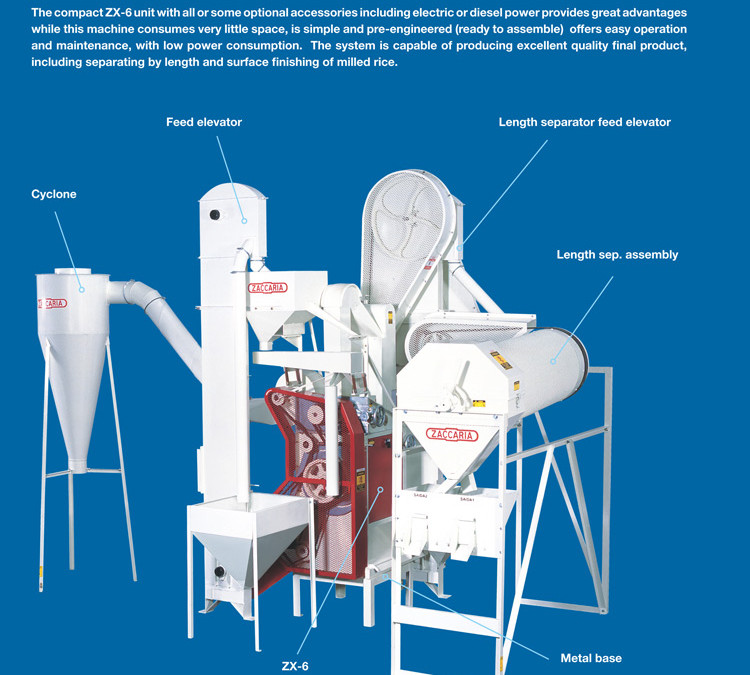

The Zaccaria ZX-6 rice milling machine is gaining a lot of attention from small farm rice farmers looking to diversify and get into the rice milling game. To most of them, it just makes sense. While not as large a significant investment as it’s bigger brother, the ZX-25 (capable of 1.5 tons per hour paddy input), the ZX-6 compact rice mill is far more attractive than it’s little brother, the ZX-3 (capable of 572 lbs per hour paddy input). The ZX-6 rice mill is capable of 1,135 paddy rice input, which is almost twice the capacity of the ZX-3, but far less than double the cost. The standard ZX-6 package includes:

- An elevator and inlet hopper to feed the paddy cleaner

- A paddy cleaner which removes large waste and small waste from your paddy before entering the mill

- A permanent magnet to remove any metals in your product prior to entering the mill

- An elevator to feed the husker

- The ZX-6 milling machine, which will husk paddy rice, remove the outer brown layer (known as bran), and aspirate the husk to the husk cyclone.

- A husk cyclone to handle your rice hulls from the husker

- An elevator and inlet hopper to feed the indent (or length separator) to give you two separations of husked rice

- The indent (or length separator) to separate your head rice from your broken kernels

- An elevator to handle the head rice and brokens to go to whatever packaging line you decide to put in

While making brown rice is more suitable to the ZX-25, the ZX-6 produces beautiful white rice ready for packaging and distribution. The capabilities are attractive, but so is the idea for a local farmer to mill his own rice and to gain an additional income by milling smaller lots of paddy rice from other local farmers in their area. It is a great way to re-capture some of the capital invested in the mill itself and to offset the risk that some farmers see in taking a step into the unknown world of rice milling. www.ZaccariaUSA.com